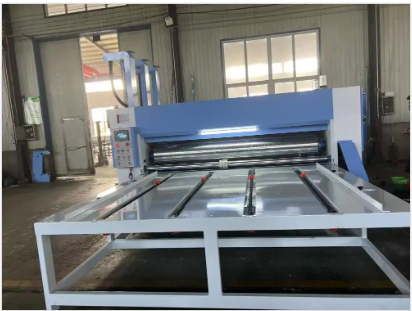

This machine is composed of 4 parts: paper feeding part, 2 sets of printing, and slotting part. It can complete three-layer and five-layer corrugated cardboard printing, slotting, creasing and other processes at one time.

machine introduction:

This machine is composed of 4 parts: paper feeding part, 2 sets of printing, and slotting part. It can complete three-layer and five-layer corrugated cardboard printing, slotting, creasing and other processes at one time.

The machine wall is made of high-quality HT250 casting, after artificial aging treatment, the thickness is 40mm, and it is processed by a large machining center to ensure the strength and processing accuracy of the wall.

The transmission gear system all adopts helical gear transmission, with low noise and high transmission accuracy, which improves the transmission stability of the gears. All transmission gears are made of high-quality alloy steel, treated with superhardness, and enclosed with spray lubrication.

The bearing adopts the famous brand bearing of Harbin Group.

The motor is adjusted by frequency converter, Delta frequency converter.

Low-voltage electrical appliances adopt Schneider.

6. Pneumatic components: The air cylinder adopts "Sono" famous brand cylinder, the solenoid valve adopts "Sono" famous brand product, and the diaphragm pump adopts "Yangtze River" famous brand ink pump.

Paper feeding system

The paper is fed by manual unloading chain.

Each paper feeding part adopts 4 hanging chains, which can adjust the size of the cardboard, and the size can be customized according to the user's requirements.

Chain tension is manually adjusted. Equipped with a counter to display the production quantity.

A pneumatic interlock control switch is installed at the rear of the equipmentto realize emergency stop and inching of the forward and reverse main engine.

The paper feeding part can be set to display the planned production quantity. When the plan is completed, the system will automatically stop and send a warning signal.

printing organization

1. Front paper guide roller

2. Printing plate roll

3. Embossing roller

4. Metal Anilox Roller

5. Rubber roller

Slotting mechanism

Before grooving, it is pre-pressed and then pressed. The cardboard is not easy to break and the boxes are neat.

The gap dial of the crimping wheel is manually adjusted, the adjustment range is 2-12mm, and the cross slider mechanism is adopted, and the transmission gear is always in the correct meshing state during adjustment.

COPYRIGHT©2011~2022 Dongguang Zhuoya Packaging Machinery Manufacturing Co., Ltd All Rights Reserved.