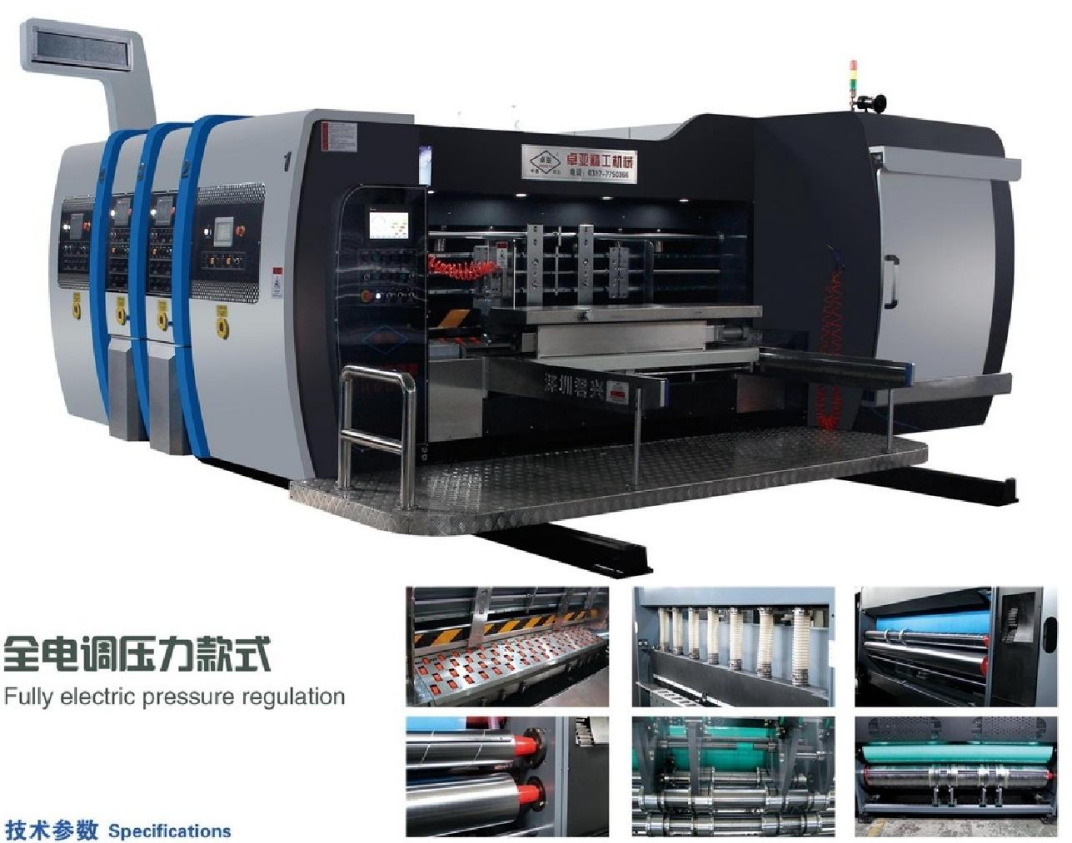

The components of this machine include a feeding and conveying device, a printing device, a slottinging device and a die-cutting device, which can realize the printing, slotting and die-cutting processes of corrugated cardboard.

-The electrical appliances and computer software of the whole machine adopt famous international brands, and the quality is stable and reliable. It adopts a man-machine interface, multiple touch screen controls, computer order management, easy operation, and faster order changes (999 orders can be stored in advance).

- The wall panels and important components of the whole machine are all subjected to aging treatment and tempered to eliminate the internal stress of the metal; they are all produced by high-precision machining centers and processed by CNC grinding machines.

- The shafts and rollers of the whole machine are made of high-quality steel, ground and processed, high-precision computer dynamic balance correction, and the surface is plated with hard chrome.

- The transmission gears of the whole machine are all made of 20CrMnTi alloy steel, carburized and quenched, and the hardness is HRC58~62: After gear grinding, the precision of six grades ensures high color registration accuracy for long-term use.

-The transmission parts of the whole machine (shaft and tooth joints) all adopt keyless connections (expansion sleeves) to eliminate connection gaps

and are suitable for long-term high-speed operation with high torque.

- The transmission bearings of the whole machine and the important transmission parts all adopt reinforced self-aligning bearings, which are easy to

maintain and have a longer service life.(Using three famous brands:"Havalo")

- The lubricating system of the whole machine adopts spray-type automatic lubrication and is equipped with an automatic balancing device to keep

the oil level of each unit at the same level.

-The whole machine adjusts the preset position function, paper feeding, printing, slotting, die cutting, automatic zero reset, and automatic reset of

the split and combined memory.

-The working clearance adjustment of the whole machine adopts wrench-free quick adjustment, and the adjustment is quick and convenient.

- The main engine adopts frequency conversion control, which makes the start and operation more stable and energy-saving.

- Equipped with an ink shortage alarm device to monitor the working status of the ink supply system in real time.

- Optional: ceramic anilox roller; scraper ink fixing system; stacker.

1 | 色组 | Color group | 可按用户需要配置to be configured according to user's needs | ||

2 | 印刷用纸 | Printing paper | A、B、C、A/B、B/C和A/B/C型瓦楞纸板(最大间隙量11mm) A,B,C,A/B,B/C and A/B/C type corrugated paperboard( the maximum interval 11mm) | ||

3 | 机器型号 | Machine model | 0920 | 1225 | 1425 |

4 | 最大过纸尺寸 | Max.paper size | 900x2200mm | 1200x2600mm | 1400x2600mm |

5 | 最大印刷面积 | Max.printing size | 900x2000mm | 1200x2500mm | 1400x2500mm |

6 | 隔张送纸 | Skip feeding paper | 1100x2200mm | 1400x2600mm | 1600x2600mm |

7 | 最小过纸尺寸 | Min,paper size | 260x500mm | 380x650mm | 380x650mm |

8 | 印刷版厚度 | Printing plate thickness | 72mm | 72mm | 72mm |

9 | 设计速度(片/分钟 | Design speed(piece/min) | 300pcs/min | 300pcs/min | 260pcs/min |

10 | 经济速度(片/分钟 | Economic speed(piece/min) | 80-260pcs/min | 80-260pcs/min | 80-220pcs/min |

11 | 套色精度 | Tinted precision | 4色(color)±0.5mm | 4色(color)±0.5mm | 4色(color)±0.5mm |

12 | 开槽精度 | Slotting precision | ±1.5mm | ±1.5mm | ±1.5mm |

13 | 最大槽深 | Max.slotting depth | 7x220mm | 7x300mm | 7x350mm |

可增加刀片,加大开槽深度increase the blade,increase the slot depth | |||||

14 | 是小开槽近距 | 正刀Positive knife 反刀Negative knife | 150x150x150x150mm 250x90x250x90mm | 170x170x170x170mm 260x90x260x90mm | 170x170x170x170mm 260x90x260x90mm |

15 | 最大模切尺寸 | Max.die-cutting size | 800x2100mm | 1100x2500mm | 1300x2600mm |

16 | 印刷辊直径(加版厚) | Printing plate diameter (contain plate thickness) | φ300mm | φ410mm | φ480mm |

COPYRIGHT©2011~2022 Dongguang Zhuoya Packaging Machinery Manufacturing Co., Ltd All Rights Reserved.